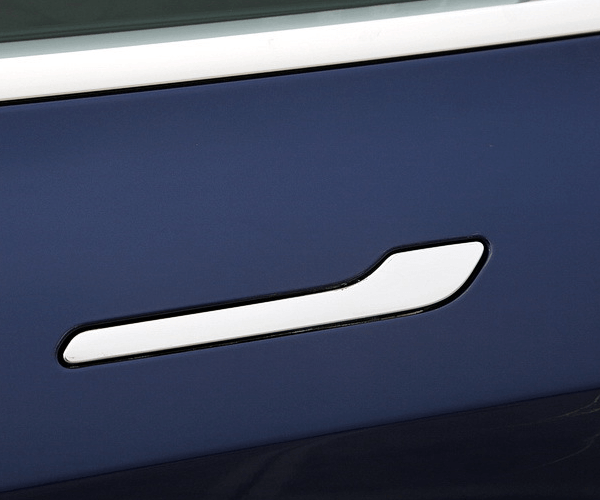

Smart Home

With the popularization of smart homes, more products are entering the home scene. Weichuang's sensitive and high-power drive system saves space while ensuring the safe operation of all components, helping enterprises produce products that meet the humanized needs of consumers and better cater to the consumer market.